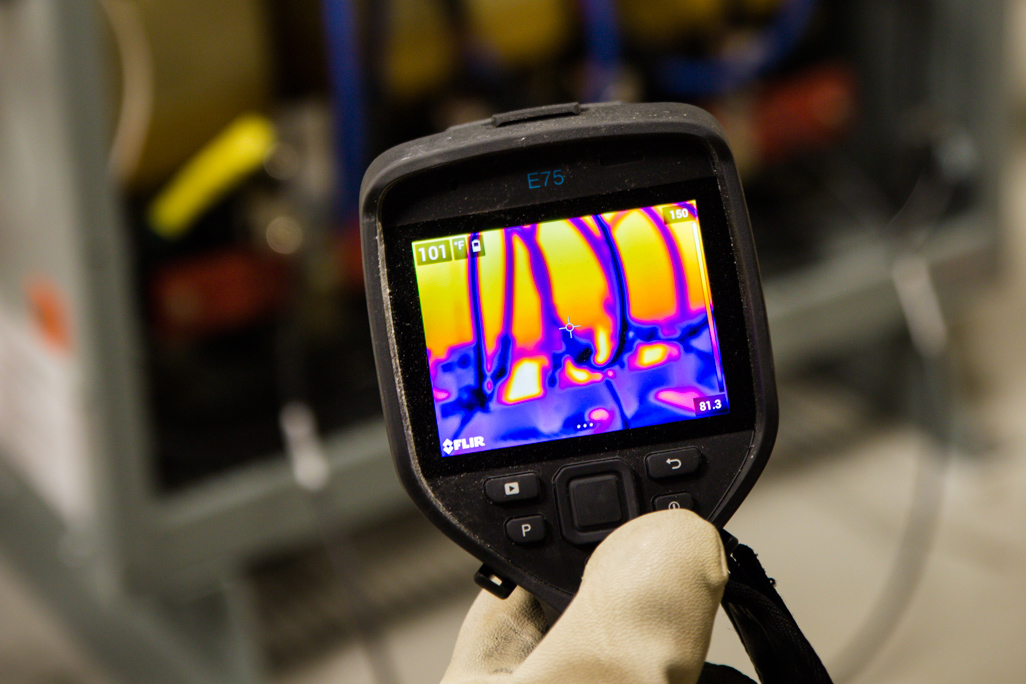

Infrared thermography

annual inspections are the standard

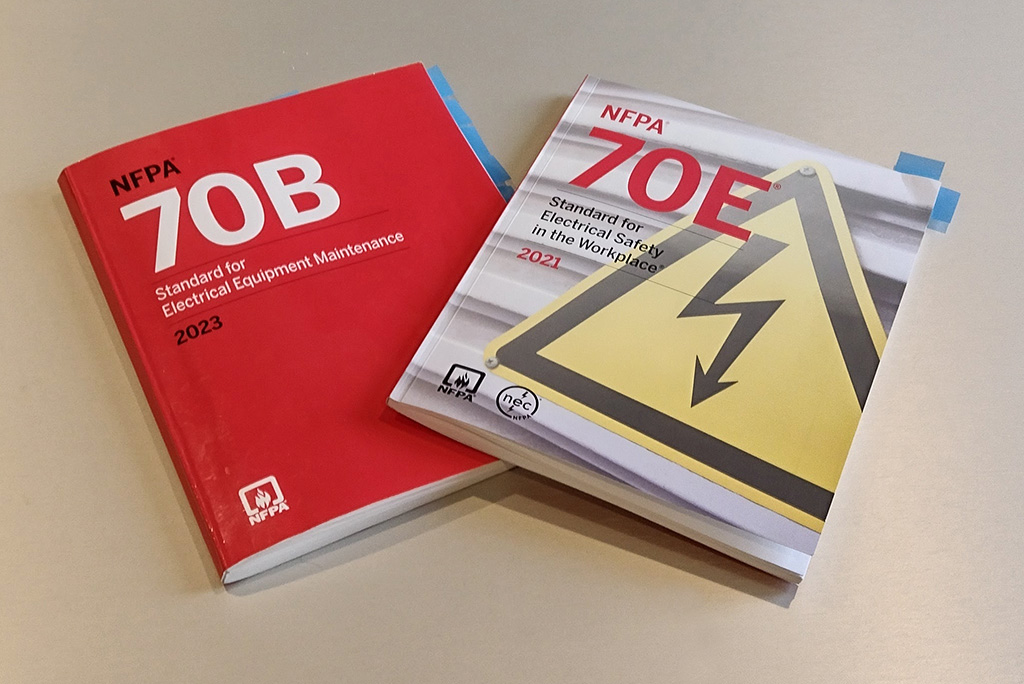

The NFPA 70B is a vital component for assuring electrical safety and maintenance standards. One of the most significant changes in the 2023 edition involves Infrared Thermography Inspections. An annual inspection is now required for all electrical equipment.

An Essential Tool for Efficient & Proactive Electrical Maintenance

Infrared thermography is crucial for electrical maintenance due to its ability to identify and visualize temperature variations in electrical components. This technology is widely used in the field for several important reasons:

Early Detection of Issues

Infrared thermography allows technicians to identify overheating issues in electrical components before they lead to equipment failures or fires. Early detection enables proactive maintenance and reduces the risk of costly downtime.

Identifying Poor Connections

Poor electrical connections can create resistance and generate heat. Infrared thermography can detect such hotspots caused by loose or corroded connections, preventing electrical failures and improving overall system reliability.

Identifying Load Imbalances

Uneven distribution of electrical loads can result in some components working harder than others, leading to overheating. Infrared thermography helps identify load imbalances, allowing for corrective actions to be taken to distribute the load more evenly.

Reducing Downtime and Costs

The early detection of potential issues through infrared thermography allows for planned maintenance activities, reducing the likelihood of unscheduled downtime. This can result in significant cost savings by avoiding emergency repairs and production interruptions.

Ensuring Electrical Safety

Overheating in electrical systems poses a safety risk, and early detection through infrared thermography helps in maintaining a safe working environment for personnel.

Infrared thermography is an efficient and proactive means of identifying potential issues to ensure the reliability and safety of all electrical systems.

Trust the Experts

Our mission is to support your transition to NFPA 70B compliance, guaranteeing that all involved parties gain the knowledge necessary to attain optimal safety and reliability standards. Leveraging our expertise, we are well-equipped to lead your company through the processes of compliance. Contact us today to get started with an updated Electrical Maintenance Plan that is customized for your facility.

About the National Fire Protection Association (NFPA)

Founded in 1896, NFPA is a global self-funded nonprofit organization devoted to eliminating death, injury, property and economic loss due to fire, electrical and related hazards. The association delivers information and knowledge through more than 300 consensus codes and standards, research, training, education, outreach and advocacy; and by partnering with others who share an interest in furthering the NFPA mission. For more information, visit www.nfpa.org. All NFPA codes and standards can be viewed online for free at www.nfpa.org/freeaccess.

NFPA 70b Compliance

- The standard for maintenance and best practices

- Outlines when and how to perform essential electrical maintenance

Preventative Maintenance

-

Custom Built Maintenance Plans

-

Yearly Inspection and Service

-

Thermal Scanning

-

Power Quality Studies

Continental Electrical Maintenance Management Platform

- QR coded equipment

- Digital one line diagrams

- Condition tracking & scheduling

- Cost effective maintenance

what does nfpa 70b mean to you?

Let’s discuss the importance of maintenance and how CECCo’s state of the art platform keeps you compliant, protects the longevity of your equipment, prevents costly downtime, and saves you money in the long run.